RFID is an abbreviation of the Radio Frequency Identification Device. RFID is a brilliant technology of data collection that uses wireless signals to accumulate data from tags (tags- that are usually attached to objects). Radio communication occurs between the tag and the RFID smart reader. This technology automatically recognizes the object, such as assets, inventory, people, etc. The best advantage of RFID is that it can scan more than one entity at a time, unlike a barcode, which consumes loads of energy and time. For example, to scan various objects in the warehouse, you just have to place all the items near an RFID code reader without worrying about its appropriate placement. Radiofrequency technology has progressed a lot in recent years and has passed through different phases from being not so rampant to being widely accepted in most of the sectors. Talking about the supply chain process, which requires precise identification of tracking of products as well as knowledge about what inventory a corporate has, here we know about the significance of RFID in the supply chain sector.

The RFID is helping the supply chain in so many ways, which are described here.

Demand planning relies on historical sales and transaction data. It enables us to generate reliable forecasts. But Inventory forecasting becomes problematic if there is no timely and true-time data. RFID can produce precise and real-time details of work-in-progress, in-transit, and finished products. Timely information about the market demand leads to an exact forecast, improved inventory visibility, and can have an instant impact on top-line revenue by retaining lost sales.

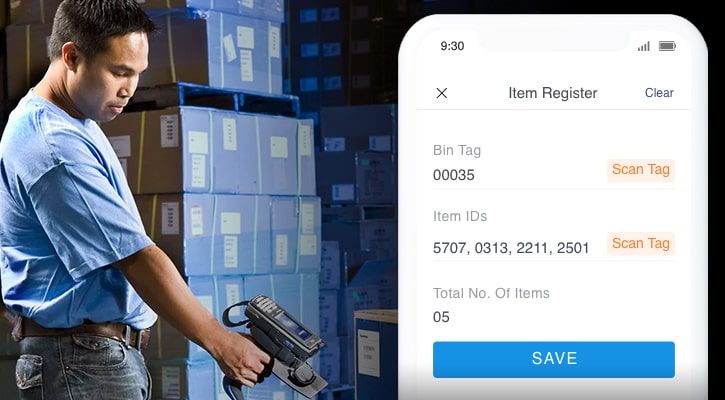

When goods are collected for shipment, the tags can be read and mechanically recorded in the system. As soon as the pallets are arranged to dispatch, the hand-held RFID code reader can read the pallet tag and confirm the shipment content while offering real-time visibility in the system. This leads to time-saving, economical process, quicker invoice settlement, decreased human error, and increases inventory precision, and simplifies the receiving process.

RFID Reader can provide additional benefits like increased speed and dexterity in locating the items, fewer human resources are required to manage the items, a decrease in the total cycle time, mechanical records of the input and output of the items and improved efficiency and cut-down reworks.